SAS PCB

Where Quality Meets Innovation in PCB Assembly

PCB Assembly Design

PCB Design for Manufacturing (DFM)

Top Tips for New Designers

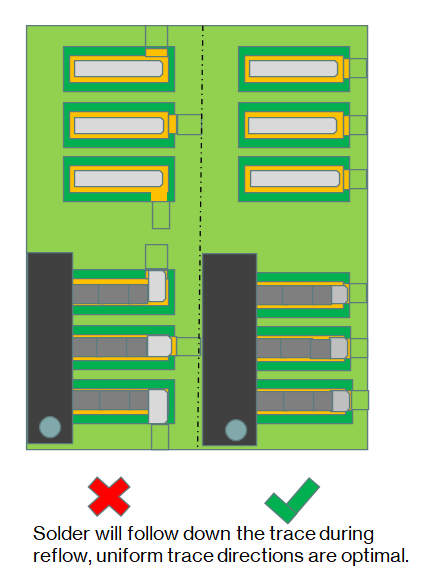

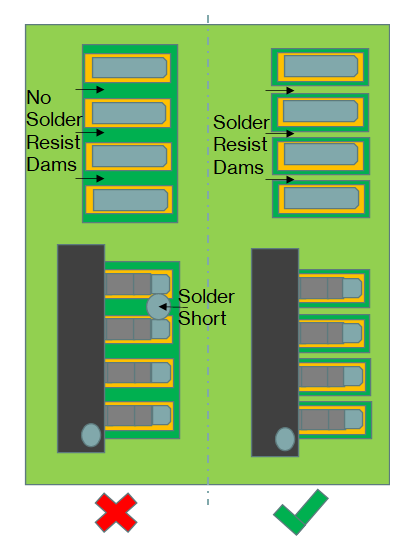

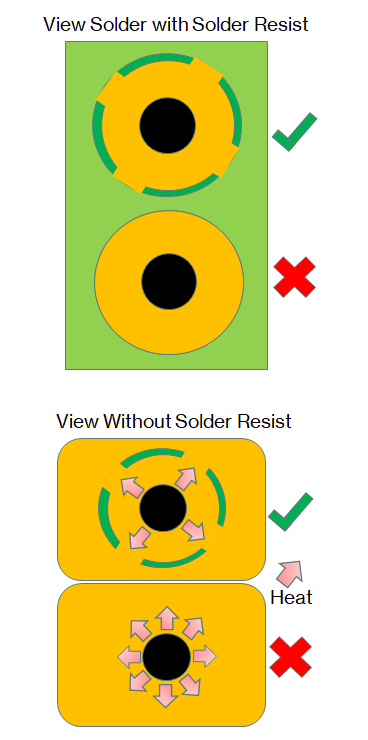

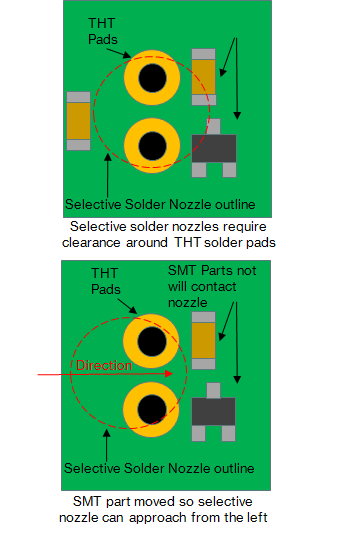

Designing a Printed Circuit Board (PCB) involves multiple iterations before achieving the perfect functionality. While some designers may overlook Design for Manufacture (DFM) considerations, SAS highly recommends incorporating DFM from the start of the design process. This helps build a functional circuit and PCB Assembly (PCBA) during the first pre-production run, ensuring the easiest PCB manufacturing experience. Just like a house needs a solid foundation, your PCB requires a solid DFM approach.

However, DFM can be intimidating, especially for new electronic designers. To help, our experienced team of engineers have compiled a list of top tips for designers creating electronic circuit boards. Click on each card for detailed information.

Do You Like What You See?

Join the ranks of satisfied engineers and businesses. Register and quote today!

Register