SAS PCB

Where Quality Meets Innovation in PCB Assembly

PCB Design For Manufacturing (DFM) Tips

Tip 08:

Position your Parts with Manufacturing in Mind

Are there Any Position Constraints?

The positioning of components in some designs is critical; a part may need to align with an external case or need to be located in a certain place on the PCB.

In most cases, though, part positions can be adjusted to make manufacturing easier and cheaper. Read some ideas below.

Try to Put All SMT Parts on One Side (if the design allows it)

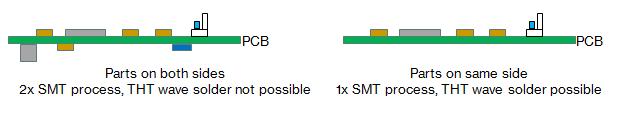

From a manufacturing point of view, having all the SMT parts in just one side is the most effective and efficient way.

However, some PCB designs will need to have a handful of parts on the second side of the PCB, which adds a lot of additional SMT time as the boards effectively have to go through the SMT process twice.

If your design allows it, try to keep all your through hole components on the same side; this allows the possibility of wave soldering, which will make the PCB assembly process cheaper.

If you Can't...

If you do need to place THT parts on both sides., or have SMT mounted one side and THT on the other, consider the spacing around THT solder side leads.

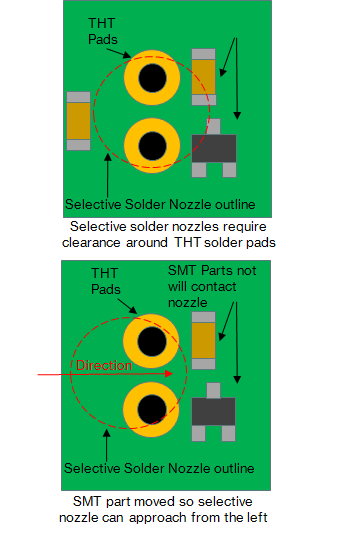

Selective solder machines can be a good automated process alternative if PCB assemblies cannot be wave soldered. However, clearance is required around solder side apertures in order to prevent solder nozzles from knocking off SMT parts during processing. Smaller micro solder nozzles can be used, but larger solder nozzles provide more consistent and quicker and cheaper results.

Try to allow at least 10mm clearance; if this is not possible, consider leaving an approach direction clear. Selective solder nozzles can be programmed to approach from a direction clear of SMT parts.

Do You Like What You See?

Join the ranks of satisfied engineers and businesses. Register and quote today!

Register